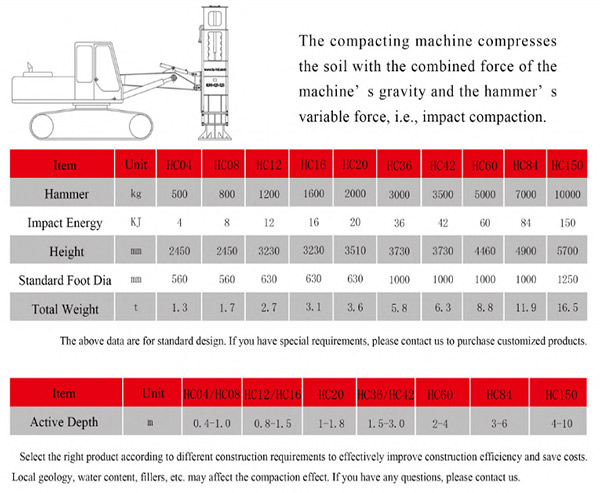

The parameters of Rapid Impact Compaction include impact energy, hammer weight, working height, working quality, ramming plate diameter, effective depth, working frequency, applicable excavator and loader models, among which impact energy, hammer weight, effective depth and working frequency are more important, which can be focused on. The following is the specification parameter table of tamping Rapid Impact Compaction for your reference.

The models of Rapid Impact Compactions include hc04, HC08, hc12, hc16, Hc20, hc36, hc42, hc60, hc84 and hc150, among which hc36 and hc42 Rapid Impact Compactions are used more. The working pressure of hc04 and HC08 is 16MPa, and the working flow is ~110l/min, which can be adapted to 7-13t excavator or 1-2T loader; Hc12 and hc16 Rapid Impact Compactions have a working pressure of 16MPa and a working flow of ~130l/min. They are used with 18-30t excavators or 3-4t loaders; Hc20 working pressure 16MPa, working flow ~130l/min, suitable for 25-36t excavator or 4-5t loader; Hc36/hc42 also has a working pressure of 16MPa and a working flow of ~160l/min. It is driven by a 30-40t excavator or a 5-6t loader; Hc60 working pressure 21MPa, working flow ~350l/min, with 36-49t excavator or loader above 8t; The working pressure of hc84 Rapid Impact Compaction is 21MPa, and the working flow is ~350l/min, which is suitable for 40-60t excavator or loader above 12t; Hc150 has a working pressure of 32Mpa and a working flow of ~600l/min, which is suitable for excavators with a capacity of more than 70t or excavators with a capacity of more than 49T.

HC series Rapid Impact Compaction can be matched with excavators or cutting machines of various brands on the market. The installation is very simple and easy to operate. After purchase, after-sales personnel will also come to install and debug, without considering how to install.

The effective compaction depth of HC series Rapid Impact Compaction can reach 10m, with a minimum of 0.4m. It is widely used in subgrade filling construction. Hc36 Rapid Impact Compaction also has a small part of hc42. HC series Rapid Impact Compaction has three tamping gears, which is suitable for PLC remote operation of tamping intensity and frequency. According to the experiment, the 3-level 9-hammer is used to strengthen the compactness of 96% of the transition area at the back of the bridge. The settlement near the abutment is more than 100mm, mostly 150~250mm, some about 300mm, the settlement in the normal rolling area is about 1000mm, the settlement at the repeated rolling position of the heavy-duty earth truck is 2000~60mm, after the normal layered filling of the high fill subgrade, the reinforcement settlement is 120~180mm every 2 layers, and the old subgrade is reinforced after excavation and rolling, with an average settlement of 200~250mm, A suitable Rapid Impact Compaction can be selected according to the above test data.

Current Position:

Current Position: