Hengda machinery is a manufacturer of hydraulic milling excavators, hydraulic rammers, hydraulic pile hammers, and hydraulic vibratory rammers. It has independent research and development capabilities. The plant covers an area of 5000 square meters. The company has passed the ISO9001 quality management system certification. It has strong production strength, product quality assurance, door-to-door installation and commissioning, and after-sales service guarantee. If you need to consult us.

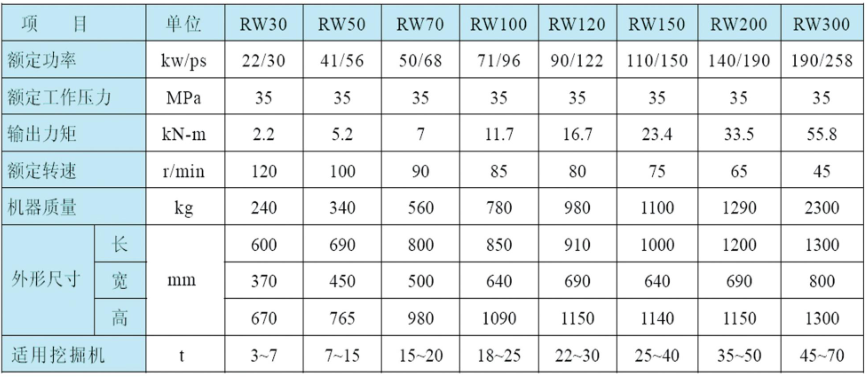

RW series horizontal hydraulic milling and excavating machine model

1. Rw30 hydraulic milling excavator, with rated power of 22/30kw/ps, rated working pressure of 35MPa, output torque of 2.2kn-m, rated speed of 120r/min, machine mass of 240kg, overall dimension of 600*370*670mm, is suitable for 3-7t excavator;

2. Rw50 hydraulic milling excavator, with rated power of 41/56kw/ps, rated working pressure of 35MPa, output torque of 5.2kn-m, rated speed of 100r/min, machine mass of 340kg, overall dimension of 690*450*765mm, is suitable for 7-15t excavator;

3. Rw70 hydraulic milling excavator, with rated power of 50/68kw/ps, rated working pressure of 35MPa, output torque of 7kn-m, rated speed of 90r/min, machine mass of 560kg, overall dimension of 800*500*980mm, is suitable for 15-20t excavator;

4. Rw100 hydraulic milling excavator, with rated power of 71/96kw/ps, rated working pressure of 35MPa, output torque of 11.7kn-m, rated speed of 85r/min, machine mass of 780kg, overall dimension of 850*640*1090mm, is suitable for 18-25t excavator;

5. Rw120 hydraulic milling excavator, with rated power of 90/122kw/ps, rated working pressure of 35MPa, output torque of 16.7kn-m, rated speed of 80r/min, machine mass of 980kg, overall dimension of 910*690*1150mm, is suitable for 22-30t excavator;

6. Rw150 hydraulic milling excavator, with rated power of 110/150kw/ps, rated working pressure of 35MPa, output torque of 23.4kn-m, rated speed of 75r/min, machine mass of 1100kg, overall dimension of 1000*640*1140mm, is suitable for 25-40t excavator;

7. Rw200 hydraulic milling excavator, with rated power of 140/190kw/ps, rated working pressure of 35MPa, output torque of 33.5kn-m, rated speed of 65r/min, machine mass of 1290kg, overall dimension of 1200*690*1150mm, is suitable for 35-50t excavator;

8. Rw300 hydraulic milling and excavating machine, with rated power of 190/258kw/ps, rated working pressure of 35MPa, output torque of 55.8kn-m, rated speed of 45r/min, machine mass of 2300kg, overall dimension of 1300*800*1300mm, is suitable for 45-70t excavator.

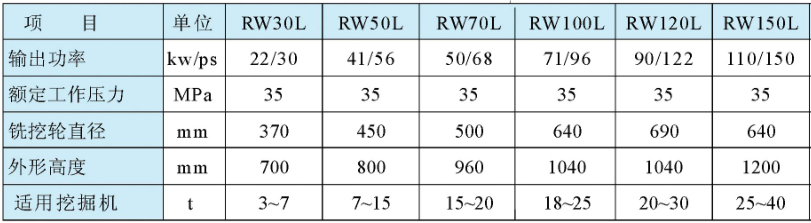

Model parameters of rw-l longitudinal hydraulic milling and excavating machine

1. Rw30l longitudinal milling and excavating machine, with output power of 22/30kw/ps, rated working pressure of 35MPa, milling and excavating wheel diameter of 370mm, outline height of 700mm, suitable for 3-7t excavator;

2. Rw50l longitudinal milling and excavating machine, with output power of 41/56kw/ps, rated working pressure of 35MPa, milling and excavating wheel diameter of 450mm, outline height of 800mm, suitable for 7-15t excavator;

3. Rw70l longitudinal milling and excavating machine, with output power of 50/68kw/ps, rated working pressure of 35MPa, milling and excavating wheel diameter of 500mm, outline height of 960mm, suitable for 15-20t excavator;

4. Rw100l longitudinal milling and excavating machine, with an output power of 71/96kw/ps, a rated working pressure of 35MPa, a milling and excavating wheel diameter of 640mm, and an outline height of 1040mm, is suitable for 18-25t excavators;

5. Rw120l longitudinal milling and excavating machine, with an output power of 90/122kw/ps, a rated working pressure of 35MPa, a milling and excavating wheel diameter of 690mm, and an outline height of 1040mm, is suitable for 20-30t excavators;

6. Rw150l longitudinal milling and excavating machine, with output power of 110/150kw/ps, rated working pressure of 35MPa, milling and excavating wheel diameter of 640mm, outline height of 1200mm, is suitable for 25-40t excavator.

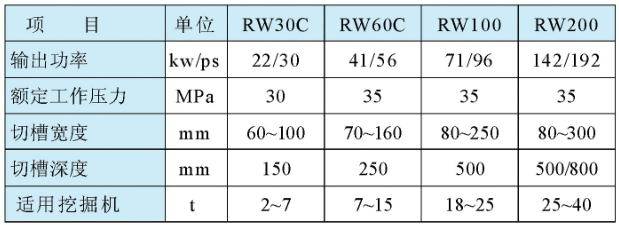

Model parameters of rw-s hydraulic grooving machine

1. Rw30c hydraulic grooving machine, with output power of 22/30kw/ps, rated working pressure of 30MPa, grooving width of 60-100mm, grooving depth of 150mm, suitable for 2-7t excavator;

2. Rw60c hydraulic grooving machine, output power 41/56kw/ps, rated working pressure 35MPa, grooving width 70-160mm, grooving depth 250mm, suitable for 7-15t excavator;

3. Rw100c hydraulic grooving machine, output power 71/96kw/ps, rated working pressure 35MPa, grooving width 80-250mm, grooving depth 500mm, suitable for 18-25t excavator;

4. Rw200c hydraulic grooving machine, with output power of 142/192kw/ps, rated working pressure of 35MPa, grooving width of 80-300mm, grooving depth of 500/800mm, is suitable for 25-40t excavator.

Price of hydraulic milling machine

The hydraulic milling and digging machine head produced by Tai'an Hengda Machinery Co., Ltd. can be installed on any type of hydraulic excavator, replacing the general configuration of bucket, crushing hammer, hydraulic shear, etc., and is suitable for many types. The price of hydraulic milling and digging head of excavator is generally between 20000 yuan and 150000 yuan, with various specifications and models, and many prices. Rammer RW series hydraulic milling and excavating machine is a new type of geotechnical hydraulic milling and excavating machine, which adopts imported hydraulic driving devices and components. If you need to buy or understand the hydraulic milling machine, please call us.

In buildings, hydraulic milling machines can solve the basic problems of buildings, such as concrete slabs and thick reinforced concrete walls. It can realize the dual functions of hydraulic crushing hammer and hydraulic tong, and can cut the reinforcement in the building at the same time. The milled material has a small particle size and can be directly used as recycled material. The grinder is very useful in the excavation of the following rocks: hard rock, weathered structure rock, layered structure rock, which can drill 80-120 tons per hour. The hydraulic milling excavator can well replace the blasting construction and protect the environment. Milling asphalt concrete or cement concrete pavement with other functions can not only replace expensive pavement hydraulic milling machines, but also complete the deep processing of large pavement hydraulic milling machines that do not work. The hydraulic milling and excavating machine can effectively remove the obstacles such as rocks, reinforced concrete, hard soil, frozen soil and tree roots encountered in the construction of highway subgrade.

The hydraulic milling excavator of Tai'an Hengda Machinery Co., Ltd. can be used for tunnel, ditch, municipal pipeline excavation, road crushing, mining, rock and frozen soil excavation, underground coal mine excavation, diversion culvert excavation, and the models are mainly RW, rw-l, rw-c. The hydraulic milling and excavating machine can also be used in the construction fields of open-pit coal mine excavation, road cleaning, steel industry, forestry and so on. In short, hydraulic milling and digging machines are widely used and easy to use.

In weathered rock and other medium and low hardness rocks, tuff can reach 25~40m3/h (different from rock density and fragmentation). The hydraulic milling machine can also mill and excavate concrete without reinforcement or with a small amount of reinforcement. The hydraulic milling and excavating machine and small hydraulic milling and excavating machine on a 20 ton excavator can easily mill and excavate concrete with a diameter of less than 30mm. Hydraulic milling and excavating machine can replace blasting construction to avoid adverse conditions such as rock strength reduction, structural looseness, local fracture caused by blasting vibration, etc. It is conducive to protecting the original self-supporting capacity of rock mass and is not easy to cause large-scale collapse; In tunnel construction, hydraulic milling machine can replace very expensive tunnel excavators, shield machines and other machinery, greatly reducing construction costs; The hydraulic milling and excavating machine is very effective in the following rock mining operations: low hardness rock, weathered structural rock, high hardness but structural layered milling and excavation volume can reach 80-120 tons (according to rock hardness); Hydraulic milling and excavating machine can replace excavator in construction and protect the environment.

1. Hydraulic milling machine can be used for tunnel excavation. In most cases, it can only be used for the excavation of tunnel contour, but in the stratum suitable for medium and low hardness rock stratum and frozen soil layer, the hydraulic milling excavator can be directly used for tunnel excavation, especially in the process of crushing excavation, with low interference to the stratum. The safety is high, and the excavation volume can reach 30-60m3 / h.

2. Hydraulic milling and excavating machine is especially suitable for areas not suitable for blasting construction; The hydraulic milling and excavating machine manufacturer has the advantages of simple operation, high controllability, clear and accurate excavation outline; The hydraulic milling and excavating machine can easily solve the problems of tunnel excavation and repair, inner surface ditch and side ditch excavation.

The existing technology of Tai'an Hengda Machinery Co., Ltd. has been used in many countries and products of various sizes. The excavator is similar to the hydraulic milling excavator installed on a special chassis. It is a kind of vehicle equipment that integrates cutting, shipping, walking, operation and other functions. It is mainly used to cut underground rock, coal or semi coal rock roadway of any shape segment. The working principle of excavator milling machine and excavator is: the hydraulic motor drives the excavator milling machine to rotate through the transmission mechanism, so that the pick installed on the milling head cuts the contact material, so that the material is stripped to reach the muzzle of the gun. The excavator also uses a motor to drive the milling head. The excavators, milling machines and excavators of the prior art are suitable for medium and low hardness rock formations and minerals. When encountering medium and high hardness rock strata, there will be phenomena of immovable milling or low efficiency, and large pick loss, so the application occasions are greatly limited.

As a new type of engineering machinery and equipment, hydraulic milling and excavating machine can be installed on any type of hydraulic excavator, which can effectively replace the general configuration of bucket, crushing hammer, hydraulic shear and so on. It is used in tunnel excavation and contour correction, channel and ditch milling and excavation, building demolition, asphalt concrete pavement milling and excavation, rock and frozen soil milling and excavation, tree root milling and excavation and other fields. The advantages of hydraulic milling machine manufacturers are: 1. Wide range of milling and excavation. In weathered rock, tuff and other low hardness rocks, the maximum milling efficiency can reach 25-120m3/h (different from rock density and fragmentation), or there is no reinforcement or a small amount of reinforced concrete, and the concrete with diameter less than 30mm can be easily milled; 2. Low vibration and noise. Blasting construction can effectively replace the restricted blasting area (such as shallow buried tunnel or rock fracture area), reduce the interference to surrounding rock and protect the environment; 3. Accurately control the construction, quickly and accurately repair the structural outline, and excavate by large-scale milling and excavation units, which can be used not only for construction units, but also for the safety of excavation units; 5. It can be used for hydraulic excavation.

In weathered rock and other medium and low hardness rocks, the tuff of excavator hydraulic milling machine can reach 25~40m3/h (different from rock density and fragmentation). The hydraulic milling machine can also mill and excavate concrete without reinforcement or with a small amount of reinforcement. The hydraulic milling and excavating machine and small hydraulic milling and excavating machine on a 20 ton excavator can easily mill and excavate concrete with a diameter of less than 30mm. Hydraulic milling and excavating machine can replace blasting construction to avoid adverse conditions such as rock strength reduction, structural looseness, local fracture caused by blasting vibration, etc. It is conducive to protecting the original self-supporting capacity of rock mass and is not easy to cause large-scale collapse; In tunnel construction, excavator hydraulic milling machine can replace very expensive tunnel excavators, shield machines and other machinery, greatly reducing construction costs; Excavator hydraulic milling machine is very effective in the following rock mining operations: low hardness rock; Weathered structural rock; The amount of milling and excavation with high hardness but layered structure can reach 80-120 tons (according to the rock hardness); Hydraulic milling machine can replace environmental protection;

The manufacturer of hydraulic milling and excavating machine can be directly used for tunnel excavation construction in medium and low hardness rock layers and frozen soil layers, especially in broken rock layers and loess. The formation disturbance is low and the safety is high. It is especially suitable for non blasting construction areas. The hydraulic milling and excavating machine has simple operation, high controllability, accurate excavation contour, and solves the problems of tunnel non excavation and repair, internal surface excavation and so on.

In the widening and deep excavation of channels, the hydraulic milling and excavating machine does not need to be refitted. It can be directly used for underwater ditch excavation and riverbed cleaning, and the width and depth can be accurately controlled to avoid over excavation. In the construction of municipal ditches, traditional operation tools such as crushing hammers and pickaxes are effectively replaced to avoid damaging the pavement and various pipelines. Milling materials can be directly used as backfill materials.

In the road demolition and maintenance operations, it can replace the expensive road hydraulic milling excavator to complete the road construction tasks such as asphalt concrete and cement concrete. The hydraulic milling excavator can effectively remove the obstacles such as rocks, reinforced concrete, hard soil, frozen soil and tree roots, so as to avoid the low efficiency of blasting operations and manual removal, and the cleared materials can be used directly.

The hydraulic milling machine can mill and excavate the foundation, concrete slab, concrete wall and building surface, and realize the dual functions of hydraulic hammer and hydraulic tong, especially in the local accurate demolition of buildings. Hydraulic milling and digging machine manufacturers have the characteristics of low noise and low vibration, which can be used in hospitals, commercial areas, schools and other occasions.

Through the above analysis, it is found that the greater the rock strength in Milling Excavation, the better the integrity, the smaller the particle size of rock debris, and the greater the slope of particle size distribution curve. For relatively complete hard rock, the rock slag milled and excavated by the manufacturer of hydraulic milling and excavating machine is mainly powder and particles, a small amount of debris and the smallest block. At this time, the mechanical efficiency of the hydraulic milling machine is consumed in the process of grinding the rock into particles and fragments. However, for rocks with poor integrity (joint and crack development) and brittle rocks, rock fragments and blocks increase significantly, and milling and excavation effects are obvious. 1.2 factors affecting the construction effect of milling and excavation.

The adaptability analysis method of hard rock tunnel milling construction needs to comprehensively consider the geological conditions of surrounding rock and equipment performance. The higher the strength of surrounding rock, the lower the efficiency of milling and excavation, and the stronger the applicability of vertical axis milling and excavation machine. Select the appropriate milling type according to the strength of surrounding rock. For tunnels with rock strength over 10ompa, horizontal axis cantilever excavators should be selected for construction; For tunnels with rock strength of 80~100mpa, the manufacturer of hydraulic milling and excavating machine should give priority to horizontal axis cantilever excavator; For tunnels with rock strength of 60~80mpa, horizontal axis or vertical axis cantilever excavators can be selected. The higher the strength of surrounding rock, the higher the power required by the milling and cutting machine. The rock strength exceeds 100MPa, and the power should be greater than 350kW; The rock strength is 80~100mpa, and the power is 300~350kw; The rock strength is 60~80mpa, and the power is about 300kW.

The hydraulic milling and excavating machine can be installed on any type of hydraulic excavator, which can effectively replace the general configuration of excavator, crushing hammer, hydraulic shear and so on. It is applied to open-pit coal mine, tunnel excavation and contour correction, channel slot milling and excavation, asphalt concrete pavement milling and excavation, rock frozen soil milling and excavation, tree root milling and excavation and other fields. Qinghai rhubarb project is mostly small section diversion tunnel, and the small section tunnel under different geological surrounding rock conditions is excavated by hydraulic milling and excavator. The application scope of hydraulic milling excavator in various rock beds is obtained, which provides a new construction method for small section tunnel excavation.

For Small Cross-section Tunnels, hydraulic milling excavators are used for excavation. First, excavate the top arc and top arch, then excavate the walls on both sides, and finally excavate the bottom stone. Before excavation and after the completion of support, the surrounding rock condition is poor, the surrounding rock condition is unstable, and the hole section is unstable.

After the excavation of the hydraulic milling excavator, cooperate with the 3m3 slag truck to discharge the slag, install the support structure immediately, spray the concrete, and then carry out the next cycle.

(1) At present, tunnel excavation in China is mainly carried out in accordance with the principles of NATM. Excavation of soft rock loess tunnel by drilling and blasting method has the advantages of short scale, long cycle time and high labor cost. For tunnels in severely weathered soft rock, blasting excavation has great interference with surrounding rock, frequent tunnel collapse, and poor control of over excavation. In the later stage, a lot of manual excavation and some manual backfilling are required. Therefore, it is particularly important to choose an efficient and low-energy soft rock excavation method.

(2) Because the tunnel section is small and the space is small, it can only be excavated by blasting. The construction technology is old and the degree of mechanization is low.

(3) Compared with the traditional blasting construction, the milling construction has less interference to the tunnel, and the construction advantage of the milling machine is obvious.

(4) The smooth blasting effect of small soft rock tunnel is poor, and the tunnel overbreak is serious; The hydraulic milling and excavating machine is used for excavation, and the formed tunnel overbreak is well controlled. There is no need to arrange personnel to backfill the overbreak part, remove or even fill the gun, which greatly reduces the manual investment.

Current Position:

Current Position: